Inner pipe sealing

Furthermore, we have specialised in internal pipe sealing and offer this service throughout Germany. You are certainly familiar with the problem when pipes burst and the water pressure in the heating system drops. With conventional pipe renovation or even complete replacement, a house is actually uninhabitable. The budget for this expenditure is usually incalculable.

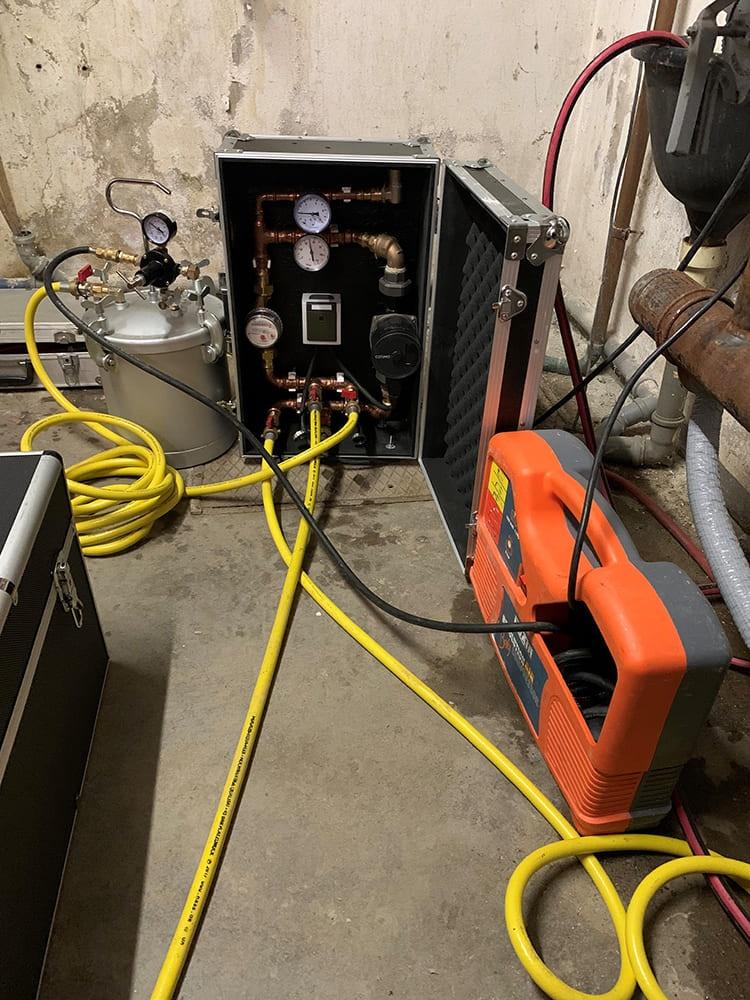

We seal problem pipes permanently and reliably from the inside, usually without tile damage. This applies to leaks with up to 1120 litres of water loss per day. For this purpose, we use a computer-controlled pump mixing station developed by us, which seals leaks in heating and fire extinguishing pipes, as well as cooling systems in on- and off-shore parks in an age-resistant manner. Another advantage is that previously unknown leaks are sealed as well.

We have the solution for you!

- We seal problem pipes permanently and reliably from the inside, mostly without tile damage

- A computer-controlled pump mixing station developed by us seals leaks in heating and fire extinguishing lines as well as cooling systems in on- and off-shore parks in an age-resistant manner

- Sealing time between 2 - 5 days, depending on the object

- Almost noiseless and dirt-free

- Leakages of up to 1120 liters per day are permanently and reliably sealed

- Previously undetected leaks are sealed with

Our advantage for you!

- Years of experience, built on our plumbing and heating construction company

- Many reference objects

- Considerable cost savings compared to conventional renovation options

- Technicians on site as contact persons

- The inner pipe sealing is offered throughout Europe

- In the event of unsuccessful sealing, we do not charge any costs

- Warranty - 3 years

We would be happy to explain the benefits of our process technology for the sealing or rehabilitation of pipelines to you in a personal meeting.

The method:

- Determine the water loss

- Determine the total volume

- Locate the leaks

- Creating the auxiliary ring line

- Installation of the pump mixing station

- Fill and deflate the entire circuit

- Adding the sealant

Now monitor the pump mixing station:

- The flow volume

- The system pressure with automatic refill and pressure boost

- Eventual temperature adjustment

- As well as the PH value of the density agent

We attribute the low number of warranty claims to the fact that we do not sell our technology to the specialised trade, but practise it exclusively from our own premises. We have been successful with this for over 20 years.

For one thing is certain:

The best technique is only as good as it is practised. The smallest deviations in our fibre materials or even the composition of the sealants determine success or failure. For this reason, every sealing station is assembled and calibrated exclusively by our experienced technicians.